Star sorting machine Rollster

| TECHNICAL PARAMETERS OF THE BASIC SECTION | |

| Dimensions of the operation area: | 1500 x 4000 mm |

| Dimensions (height/width/depth): | 1500 x 2000 x 1500 mm |

| Motor input: | 1,1 kW |

| Sorting permomance: | 100 m3/h |

ROLLSTER – reliable sorting

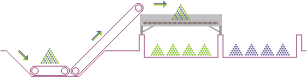

The ROLLSTER roll screen represents a highly effective screening device for classifying various types of bulk material based on the grain size. A broad range of materials earth, aggregate, asphalt, concrete, wood, slag, biomass, compost, plastics, glass, ceramics, paper, cardboard, other material contained in municipal or industrial waste can be sorted using this type of screen. A considerable advantage of the ROLLSTER roll screen is its ability to process a broad range of frequently technologically extreme materials without the risk of jamming the infeed area. This ability ensues from the applied technological design which utilizes parallel lines of rotating discs. The lines of discs rotating in one direction impart a bouncing or wavelike action into the conveyed material. The applied design virtually eliminates the likelihood of screen clogging, whereby adhesive and not very loose materials can be reliably sorted as well. The alignment, arrangement and configuration of the screen's rotating discs depend on the specific application and the customers' requirements regarding the size of the sorted fraction. Depending on the specific application, the material used to construct the individual discs also varies, from a high abrasion alloy steel to a highly durable rubber compound with increased mechanical and chemical resistance. The modular construction of basic sections, their two- or three-stage serial or parallel configurations allow for the set up of a multi-stage roll screen capable of creating up to four material fractions, in one pass, according to the grain size.

ADVANTAGES OF THE DEVICE:

- high sorting performance

- small dimensions

- self cleaning ability

- low maintenance demands

The ROLLSTER roll screen represents a highly effective screening device for classifying various types of bulk material based on the grain size. A broad range of materials earth, aggregate, asphalt, concrete, wood, slag, biomass, compost, plastics, glass, ceramics, paper, cardboard, other material contained in municipal or industrial waste can be sorted using this type of screen. A considerable advantage of the ROLLSTER roll screen is its ability to process a broad range of frequently technologically extreme materials without the risk of jamming the infeed area. This ability ensues from the applied technological design which utilizes parallel lines of rotating discs. The lines of discs rotating in one direction impart a bouncing or wavelike action into the conveyed material. The applied design virtually eliminates the likelihood of screen clogging, whereby adhesive and not very loose materials can be reliably sorted as well. The alignment, arrangement and configuration of the screen's rotating discs depend on the specific application and the customers' requirements regarding the size of the sorted fraction. Depending on the specific application, the material used to construct the individual discs also varies, from a high abrasion alloy steel to a highly durable rubber compound with increased mechanical and chemical resistance. The modular construction of basic sections, their two- or three-stage serial or parallel configurations allow for the set up of a multi-stage roll screen capable of creating up to four material fractions, in one pass, according to the grain size.

ADVANTAGES OF THE DEVICE:

- high sorting performance

- small dimensions

- self cleaning ability

- low maintenance demands